Precision Unveiled: Advanced Rigid-Flex PCB Production Techniques for Aerospace and Military Applications

- Flex Plus Tech team

- Jan 16, 2024

- 2 min read

Updated: Mar 12, 2025

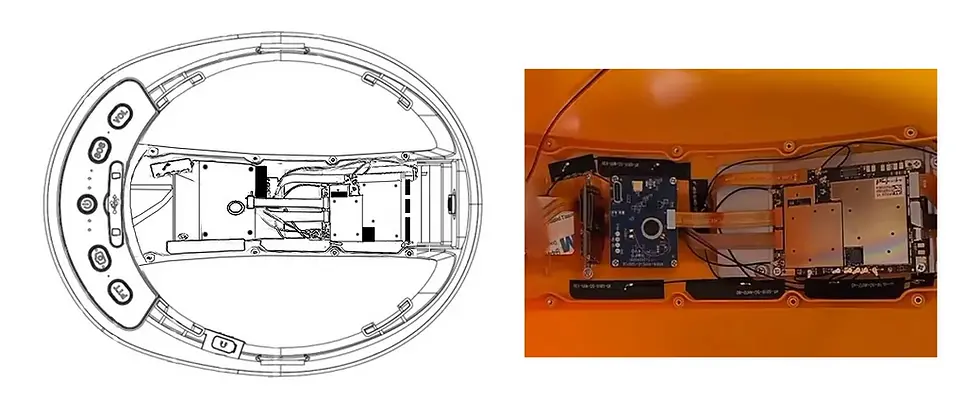

In the landscape of electronic manufacturing, where exacting standards define aerospace and military applications, the significance of precision and reliability cannot be overstated. Rigid-flex printed circuit boards stand as indispensable components, seamlessly merging flexibility and rigidity. Beyond mere plating techniques, this article explores the intricacies of Rigid-Flex production methods, unraveling the precision and innovation inherent in one of the Flex PCB manufacturing processes. Focusing on key elements such as lead-tin alloys, robust plating in copper-plated via holes, and the application of lead-tin solder spray and hot air-leveling, we unveil the meticulous craftsmanship behind Flex PCBs tailored for the demands of Aerospace and Military Applications, exclusively from Flex Plus.

Lead-Tin Alloys in Rigid-Flex Production

Flexibility meets reliability with the use of lead-tin alloys in Rigid-Flex PCB. These alloys offer exceptional solderability, which is crucial for aerospace and military applications where secure connections are non-negotiable. The controlled alloy composition ensures a perfect balance between malleability and structural integrity, allowing Rigid-Flex PCBs to withstand the demanding conditions often encountered in aerospace and military environments.

Robust Plating in Copper-Plated Via Holes

In aerospace and military-grade Rigid-Flex PCBs, the integrity of every connection is paramount. The plating in copper-plated holes takes center stage, with a minimum thickness requirement of 25 microns (around 1 mil) or above. This robust plating ensures superior conductivity, resilience against different tough environmental factors, and longevity even in the harshest conditions. Each copper-plated via is meticulously crafted to meet or exceed aerospace and military specifications, guaranteeing unmatched reliability.

Lead-Tin Solder Spray and Hot Air-Leveling

At Flex Plus, our application of lead-tin solder spray and hot air-leveling techniques represents the pinnacle of precision in aerospace and military-grade Rigid-Flex PCB manufacturing. Going beyond, our solder spray ensures not only even and meticulous coverage but also optimal adhesion, resulting in the formation of secure and durable solder joints of the entire Rigid-Flex PCB, el

ability to new heights and seamlessly facilitating integration into aerospace and military electronic systems.

Why Rigid-Flex PCB for Aerospace and Military Applications?

Advancing Aerospace and Military Technologies with Flexibility and Reliability

In the dynamic landscape of aerospace and military technologies, Rigid-Flex PCBs produced with these advanced techniques from Flex Plus stand as a testament to unwavering commitment. The fusion of flexibility and reliability achieved through precision processes, lead-tin alloys, robust copper-plated hole plating, and meticulous soldering techniques positions Flex Plus as the leading Chinese manufacturer in delivering innovative solutions for aerospace and military applications.

As aerospace and military requirements evolve, the demand for Rigid-Flex PCB that can withstand the rigors of modern applications becomes more critical. Flex Plus rises to the challenge, providing aerospace and military-grade precision that propels technological advancements forward, ensuring the highest levels of performance, durability, and security in every Rigid-Flex PCB produced.

Contact us for tailored FPC quotes with your plating requirements from here.

reach gm02@fpc-plus.com for sending your drawings and requests

Comments